Peel Testeragencies|t peel testing procedure : manufacturer FP-2260 Friction/Peel Tester: The FP-2260 tester conducts T-peel, 90-degree and 180-degree peel tests on packaging, adhesive, paperboard, label, paper and film materials. The results identify the peel properties. Up to 128 instances of peel test results data can be stored in the system for later review. The load cells are interchangeable.

Resultado da Protégez votre compte en activant l'A2F. En guise de récompense, vous recevrez l'emote Boogie Down pour Fortnite Battle Royale.

{plog:ftitle_list}

Resultado da to continue to live after someone, especially a member of your family, has died: He is survived by his wife and four children. Fewer examples. There's .

what is peel testing

ADMET offers a variety of peel testing machines that are ideal for measuring the peel strength of elastomers, adhesives, glues, cement, laminates, packaging, fabrics, coatings, labels, tapes, .Home / Force Applications / IPTS 180 Degree Peel Tester IPTS 180 Degree Peel Tester. Models: IPTS-1 capacity 1 lbf IPTS-4 capacity 4 lbf IPTS-11 capacity 11 lbf. 15″ (400 mm) stroke, peel for tapes and other adhesive material; Speed . A peel strength tester, also known as a peel tester or peel adhesion tester, is a specialized piece of equipment designed to determine the force required to peel apart the layers of a material or seal. It is a valuable tool .

Peel tests are performed on universal testing machines that consists of a test frame that is equipped with a load cell, testing software, and application-specific grips and accessories. Many peel tests require the use of a specialized test .

• 180 degree peel, COF hardware standard • Embedded microprocessor permits self-contained, stand-alone operation • Running and lot statistics (Mean, Standard Deviation, Coefficient of Variation) • Automatic balance and calibration SP-2100 adds these features, as standard (included in base price): .

FP-2260 Friction/Peel Tester: The FP-2260 tester conducts T-peel, 90-degree and 180-degree peel tests on packaging, adhesive, paperboard, label, paper and film materials. The results identify the peel properties. Up to 128 instances of peel test results data can be stored in the system for later review. The load cells are interchangeable.This Coefficient of Friction Tester (COF) / Peel Tester can measure the static and kinetic coefficient of friction as well as run seal strength tests, 180° peel, 90° peel, and T-peel tests. The FP-2260 also offers a tensile test mode to perform lightweight tensile tests up to 10 kg (22 lbs).Peel Force Tester Description: Peel Force Tester. Model: PL425. Specification: Peel angel: 165-180 degree; Pull length: 50-200mm; Japan ALGOL electronic Rally: display range MAX 1000.0 gf. Test speed: Max 300mm / min; Power: single-phase AC 110V / AC 220V. Dimensions (mm): Length 900 x Width 230 x Height:120;

Peel tests are performed on universal testing machines that consists of a test frame that is equipped with a load cell, testing software, and application-specific grips and accessories. Many peel tests require the use of a specialized test fixture that maintains the specified peel angle throughout the test. 180° and T-peel testing require only tensile grips.

Peel strength tester is mainly used to measure the peel strength of cooper foil in CCL and PCB physics laboratory according to IPC-TM-650 --Feature-- 1.Equipment with high precision tension meter of LED digital screen, which is convenient for user to check the result.According to ASTM D3330, specimens for the peel test must be prepared from pressure-sensitive tape of a specific size in order to measure the peel adhesion. The exact dimensions of the specimens vary according to the test method within the standard. In general, however, the specimens must be cut to meet the specified width and length requirements to ensure .

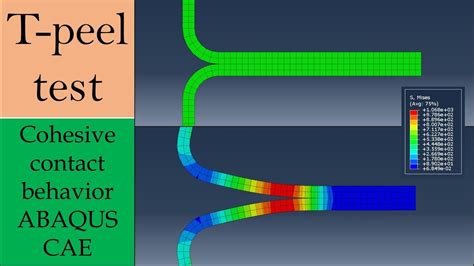

The phase angles must be known in order to assess and perform a peel test, and the adhesive strength varies with peeling angle. Methods of testing range from the following. Single-coated, peel at a 180-degree angle. (Single-coated film) Peeled at a right angle to the surface. Evaluation of bond flexibility by T-peel testThus, in such fields peel strength evaluation is indispensable for evaluating durability and reliability of adhesive bonds. The purpose of the Peel strength tester is to accurately calculate the amount of force required in separating two materials joined by an adhesive. This involves estimating the adhesive’s strength as well as the overall .This advanced Peel Tester for Adhesives is designed and engineered in accordance with international test standards including: ASTM D3330 (Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape) ISO 8510-2:2006 (Adhesives — Peel test for a flexible-bonded-to-rigid test specimen assembly — Part 2: 180 degree peel)Peel strength, the average force required to separate two bonded materials from one another, is a property applicable to various industries including aerospace, automotive, adhesives, packaging, biomaterials, microelectronics, and more. Peel test data is used to determine the quality of the adhesive joint and, where applicable, provides information on the effects of processes

Preliminary Pages 6 M10-14197-EN Hazard - Set the appropriate limits before performing loop tuning or running waveforms or tests. Operational limits are included within your testing system to suspend motion orPeel Strength testing is a simple mechanical test method which measures the peel separation strength of two flexible materials which have been adhered or bonded together. It is also known as the “ T-Peel ” test because of the sample shape, which resembles the letter “T” when the sample is loaded on the machine before the peel testing.

t peel testing procedure

Peel testing allows accurate measurement of the performance of seals, coatings and adhesives and gives invaluable information to resolve failure investigations for adhesives failure and optimize processing parameters. Seals, laminates and adhesives have been designed to perform many functions. Some applications allow easy to peel flexible .Imada offers motorized peel testers in several different peel configurations. Each tester includes special attachments for the appropriate peel type. Skip to content. Imada Inc. Force & Torque Measurement ISO 9001 Registered & ISO/IEC 17025 Accredited. Call Toll Free 1-800-373-9989 Email IMADA. Search for: Menu . Company;Peel Strength Test: A Step-by-Step Guide . The strip strength testing strategy ordinarily includes the following advances: Sample Planning: Manufacturers prepare samples according to applicable norms like ASTM D 1876, which establishes standard test techniques for peel resistance of adhesives. The test samples normally comprise two reinforced .The strong gripping clamps are specially designed to perform peel tests at 180 degrees, which is the standard angle for most peel tests. The Presto Peel Adhesion Tester also comes equipped with an inbuilt calibration facility, which allows for easy and quick calibration of the instrument to ensure the accuracy of the results.

A peel test is a fundamental mechanical test that measures the properties of an adhesive bond. Peel tests involve applying a tensile force to a flexible substrate that is bound by an adhesive to either another flexible substrate (such as tape, thin film, or rubber) or a rigid substrate (such as metal, rigid plastic, or composite).

Peel strength is the average load per unit width of bond line required to separate bonded materials where the angle of separation is 180 degrees. Learn more about 180 degree peel testing in the application note 180 Degree Peel Test on Syringe Blister Pack. Typical graph showing a peel strength test: The tack of prepreg is a key factor affecting the automatic tape laying process. During the manufacturing process of large composite parts, prepreg material may be stored at room temperature for several days, resulting in a decrease in its tack. In this study, a new tack test tool was designed, and the decay rate of prepreg tack at different temperatures was . Peel Adhesion Tester: An Overview of the Machine. A peel adhesion tester is a specialized instrument designed to measure the adhesive strength of materials, including tapes, labels, films, and other packaging components. It simulates real-world scenarios by applying a controlled force to peel apart two surfaces bonded with adhesive.Applications of Peel Testing. Peel test machines are used extensively across various sectors, including: Packaging: To ensure seals on packaging materials remain intact during transportation.; Medical Devices: To verify the reliability of adhesive bonds in medical applications.; Textiles: To assess adhesive strength in fabric lamination.; Tape Peel Adhesion Testing

ASTM D3330 is a major peel testing standard that outlines the requirements for determining the peel adhesion properties of pressure-sensitive tapes such as surgical, electrical, packing, and duct tape. The standard includes 6 different methods (A-F) for measuring peel adhesion with both 90° and 180° peel tests.Peel Fixture. P90-200N 90° Peel Table – Maintains 90 degree peel position; The 90 degree peel tester performs quick and efficient peel tests. The 90 degree peel test system is comprised of the 90° peel table, film grip, motorized test stand and digital force gauge. The slide bearing table moves as the sample peels to maintain a constant 90 .

Remastered - STEAMUNLOCKED » Free Steam Games Pr.

Peel Testeragencies|t peel testing procedure